Grocery Packing Automation: How AI Robots Are Revolutionizing Fulfillment in Minutes

What Is Grocery Packing Automation?

Grocery packing automation refers to the use of robots and artificial intelligence to pick, sort, and pack grocery items in fulfillment centers. Instead of humans walking aisles and manually collecting items, robots now complete this process in a fraction of the time, with a much lower error rate.

This technology leverages:

- AI algorithms for decision-making,

- robotic arms for handling products,

- automated conveyor belts for movement,

- and cloud-based inventory systems for real-time management.

It’s the intersection of AI, robotics, warehouse automation, and logistics optimization—a powerful combination that aims to make grocery delivery faster, cheaper, and more accurate.

How AI-Powered Robots Work in Grocery Packing

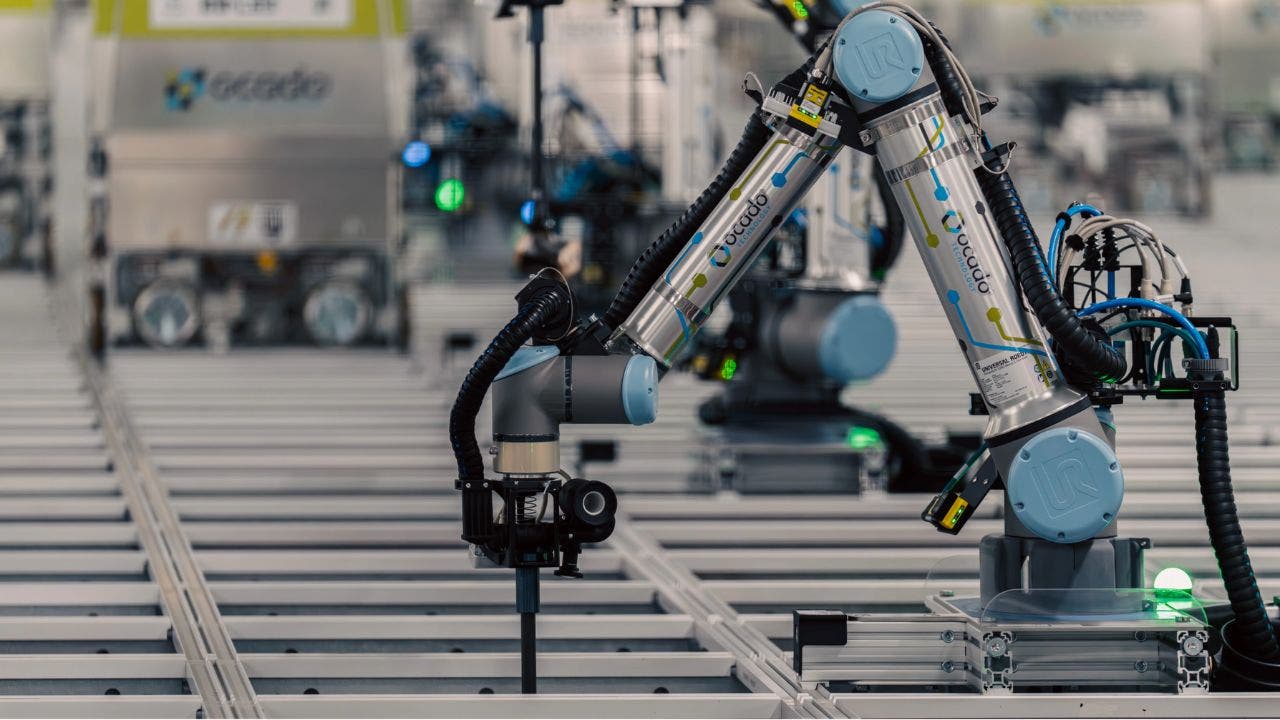

One of the most compelling examples of grocery packing automation is Ocado’s Hive system, recently featured in a Fox News article.

At the heart of Ocado’s innovation lies a grid-based warehouse, where over 1,000 robots move in synchronized precision across a metallic framework. These AI-powered bots, using swarm intelligence, retrieve storage bins from stacks below and bring them to stationary packing stations. Human intervention is minimal.

Each robot communicates wirelessly with a central system that:

- Assigns tasks based on order priority.

- Monitors location to avoid collisions.

- Optimizes energy use and timing.

- Adjusts in real-time based on demand fluctuations.

The result? A grocery order that might take 30 minutes manually can now be packed in under five minutes with 99.9% accuracy.

Benefits of Grocery Packing Automation

The shift to automation in grocery logistics brings undeniable advantages, especially in an age where speed and precision define customer satisfaction. Here are some key benefits:

⚡ Unmatched Speed and Efficiency

Robots don’t need breaks. They can operate 24/7, enabling same-day or even same-hour grocery deliveries. This helps companies meet growing consumer expectations without overwhelming their workforce.

✅ Accuracy and Order Integrity

AI systems significantly reduce human error. From scanning barcodes to selecting fragile items, robots are programmed to follow precise protocols, ensuring fewer mistakes and returns.

📉 Lower Labor and Operational Costs

While the initial investment in automation is substantial, it pays off over time. Labor costs decrease, and automation improves energy efficiency and spatial utilization within warehouses.

🔄 Scalability and Consistency

Automated systems are easily scalable. As demand increases, more robots can be added without impacting workflow consistency—a major advantage during peak seasons or viral trends.

🧼 Safety and Hygiene

Post-pandemic, hygiene has become critical. Robotic systems reduce human contact with food items, improving cleanliness and safety standards across the supply chain.

Real-World Example: Ocado’s Hive System

Let’s take a closer look at Ocado, a UK-based online grocer that has pioneered one of the most advanced grocery fulfillment systems in the world.

In their automated warehouse, more than a thousand robots communicate over 4G networks, zipping across the grid at speeds up to 13 feet per second. They pick up totes containing food items and bring them to a human packer or another robot for boxing. The system can process up to 65,000 orders per week.

What makes Ocado’s setup unique:

- The grid design enables efficient use of vertical space.

- AI adjusts robot movement patterns dynamically.

- The software predicts demand spikes and pre-sorts items.

- Machine learning continuously refines the packing algorithm.

This isn’t just automation—it’s smart automation, and it’s setting the standard for the future.

The Future of Grocery Packing Automation

While grocery packing automation is already impressive, the future holds even more promise.

🚀 AI + IoT + 5G = Hyper-Automation

With 5G connectivity and edge computing, robots will process data faster and become even more autonomous. IoT sensors will track temperature, item freshness, and expiration dates in real time.

🤖 Integration with Delivery Drones and Robots

We’re not far from a world where the entire process—from packing to doorstep delivery—is automated. Companies like Amazon and Walmart are experimenting with drone and ground robot delivery systems, which could plug directly into automated warehouses.

🌐 Global Adoption, Local Impact

Emerging markets are beginning to embrace this technology, driven by rising online grocery demand. In India, for instance, large grocers and startups may soon implement affordable automation solutions to gain a competitive edge.

🌱 Sustainability and Energy Efficiency

As AI optimizes packaging material usage and robotic fleets become more energy-conscious, the environmental impact of logistics could reduce drastically—an important step toward greener retail.

Challenges & Considerations

Of course, no revolution comes without roadblocks. Grocery packing automation has its share of challenges:

💸 High Upfront Costs

Building a fully automated warehouse requires millions in capital expenditure. This creates a barrier for small and mid-sized retailers, limiting adoption in some markets.

👷♂️ Workforce Displacement

As robots take over repetitive tasks, human workers may be displaced. However, there’s also potential to retrain employees for higher-skilled roles in robotics maintenance, system operations, and data management.

⚠️ Technical Complexity

Automated systems rely heavily on software, hardware, and data synchronization. Any failure—whether a server crash or robot malfunction—can disrupt operations and cause losses.

🔐 Data Privacy and Security

With automation comes data—lots of it. Ensuring that customer information and operational data are secure will be critical for trust and compliance.

Conclusion

Grocery packing automation is no longer just a futuristic concept—it’s a reality shaping how we buy, store, and receive our groceries. Thanks to AI, robotics, and warehouse innovation, companies like Ocado are proving that the future of retail is fast, smart, and incredibly efficient.

As more retailers turn to automation to meet demand, cut costs, and improve service, it’s clear that this technology is not just an upgrade—it’s the new standard. Whether you’re in tech, retail, logistics, or just a curious consumer, this is a trend worth watching.

FAQs

❓What is grocery packing automation?

Grocery packing automation uses AI-powered robots and smart systems to pick, sort, and pack groceries in fulfillment centers, minimizing human involvement and maximizing speed and accuracy.

❓How do robots pack groceries so fast?

Robots in systems like Ocado’s Hive operate on a smart grid, using AI to coordinate movement and minimize delays. Some robots can process an entire order in under five minutes.

❓Which companies use grocery packing automation?

Ocado, Amazon, Walmart, and several Asian e-grocery startups are implementing or experimenting with automated fulfillment solutions.

❓Is grocery packing automation cost-effective?

Yes, in the long term. While initial setup is expensive, reduced labor costs, improved efficiency, and scalability provide a strong ROI.

❓Will automation replace grocery workers?

It may reduce some manual roles but also opens opportunities in tech, robotics maintenance, AI management, and logistics optimization.

📌 Want more insights on AI in logistics, retail automation, or tech trends? Explore our AI & Retail category.